Unified national service hotline

NEWS

CONTACT US

Tel:0769-85228059 85194860

Fax:0769-85245586

After-sales service line:0769-85529591

Mail:fu328@126.com

Add:No. 3, Xinlian Xinxing Road, Humen, Dongguan, Guangdong

Taiwan: No. 5, Jingke 7th Road, Nantun District, Taichung City

NEWS CENTER

Introduction of automatic high-efficiency aluminum cutting machine compound production line

- Author:

- Origin:

- Time of issue:2019-01-21 16:17

- Pageviews:

(Summary description)This fully automatic high-efficiency aluminum cutting composite production line is composed of a fully automatic aluminum cutting machine CNC-610, an automatic feeding mechanism, a system power unit, a discharging device, and a finished product storage device.

Introduction of automatic high-efficiency aluminum cutting machine compound production line

(Summary description)This fully automatic high-efficiency aluminum cutting composite production line is composed of a fully automatic aluminum cutting machine CNC-610, an automatic feeding mechanism, a system power unit, a discharging device, and a finished product storage device.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2019-01-21 16:17

- Views:0

Introduction of Jincheng Machinery-Fully Automatic High-efficiency Aluminum Cutting Machine Compound Production Line

This fully automatic high-efficiency aluminum cutting composite production line is composed of a fully automatic aluminum cutting machine CNC-610, an automatic feeding mechanism, a system power unit, a discharging device, and a finished product storage device.

CNC610 Crosscut Sawing Ability Analysis Table

Features of Fully Automatic High-efficiency Aluminum Cutting Machine Compound Production Line:

The manipulator automatically loads the material, the automatic drum conveys the raw material to the sawing positioning area, the automatic sawing 610, automatic separation, the conveyor belt automatically unloads and conveys, when multiple pieces of sawing, the discharge conveyor belt automatically releases the product, and automatically conveys it to High-definition camera detection area, automatic detection, the detection is completed, the conveyor belt is automatically transferred to the robotic arm to place the finished product packaging area, and the robotic arm is automatically placed to complete the packaging, forming a fully automatic unmanned assembly line production.

Feeding mechanism:

The feed adopts roller-type linear slide rail, which has strong bearing capacity, high precision, strong stability, long service life, no damage to the surface of the workpiece, and high feeding accuracy. The feeding part adopts double-guide self-lubricating oil-free bearings to clamp on all sides, which is fast and accurate, stable and balanced, does not damage the material, and the pressing height is adjustable.

Power system device:

The servo motor drives the ball screw with high accuracy, suitable for NC controller, and high stability of PLC control.

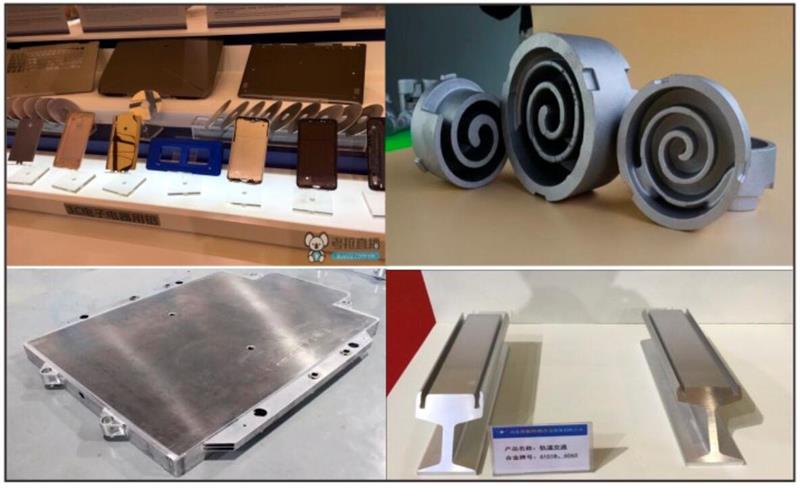

Cutting samples:

Scan the QR code to read on your phone