Unified national service hotline

NEWS

CONTACT US

Tel:0769-85228059 85194860

Fax:0769-85245586

After-sales service line:0769-85529591

Mail:fu328@126.com

Add:No. 3, Xinlian Xinxing Road, Humen, Dongguan, Guangdong

Taiwan: No. 5, Jingke 7th Road, Nantun District, Taichung City

NEWS CENTER

Expose it-Why is Jincheng Machinery JC-610-2A semi-automatic aluminum cutting machine so hot!

- Author:

- Origin:

- Time of issue:2019-05-15 13:33

- Pageviews:

(Summary description)Recently, many customers came to consult Jincheng Machinery JC-610-2A semi-automatic aluminum cutting machine. Let's take a look at the characteristics of this machine.

Expose it-Why is Jincheng Machinery JC-610-2A semi-automatic aluminum cutting machine so hot!

(Summary description)Recently, many customers came to consult Jincheng Machinery JC-610-2A semi-automatic aluminum cutting machine. Let's take a look at the characteristics of this machine.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2019-05-15 13:33

- Views:0

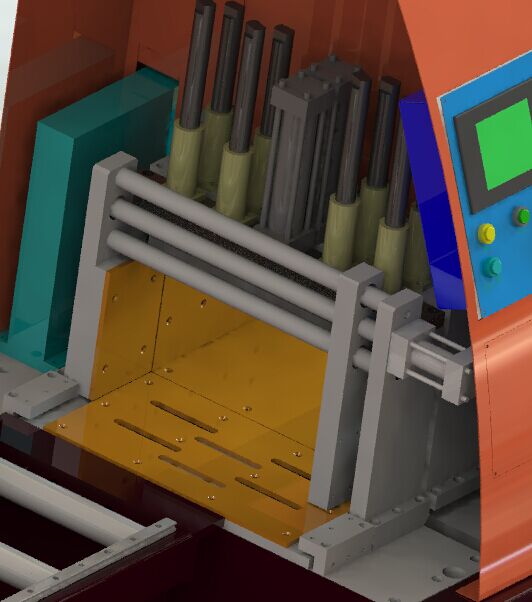

Recently, many customers came to consult Jincheng Machinery JC-610-2A semi-automatic aluminum cutting machine. Let's take a look at the characteristics of this machine.

First of all, let us first understand the composition and specific performance of the JC-610-2A semi-automatic aluminum cutting machine

1. Machine performance:

①First, manually carry out feeding and discharging-design side and upper and lower material pressing devices in 2 directions above and outside the sawing table. In order to ensure that the profile sent to the sawing table is perpendicular to the saw blade, a positioning machine parallel to the fixed end surface of the sawing table is designed on the inside of the bracket of the sizing table to ensure that the sawing starts after the material is compressed, and the side is designed on the outside of the sizing table. Square pressing device. (Sizing table is optional)

②The hollow structure is designed under the sawing table, and the table has several grooves to facilitate the leakage of aluminum chips during sawing. The aluminum chips that are leaked are designed with an inclined surface mechanism and collected from the back of the sawing table. In order to prevent the aluminum scrap box from being blocked, it is necessary to manually clean and collect it from the opening with an air gun.

③The aluminum scrap collection device under the sawing table is designed with a protective structure that is connected to the motor and the sawing table extending out of the machine

④The main machine of the sawing table is designed with an automatic chip suction port. The bottom of the sawing table is designed with a deflection type chip collecting device to facilitate the thorough cleaning of aluminum chips.

⑤Adopting digital display, length adjustment is easy, fast and accurate.

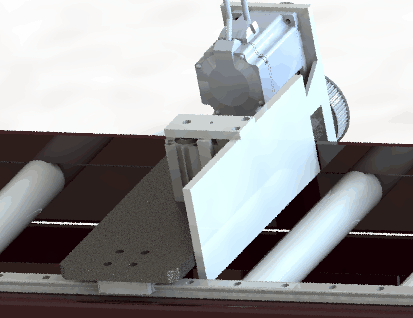

2. Features of aluminum scrap recovery device:

An inclined collecting trough with the same length is designed under the fixed-length supporting rack rail. It is operated manually by blowing material from the sawing end to the fixed-length end. The fixed-length board has slots or holes, and no vacuum cleaner is designed.

3. Feeding and unloading methods

①The method of manually pushing materials from the existing cooling bed to the sawing table is adopted, and the total width of each pushing material is determined by manual operation.

②The sawed material is manually framed after the material is divided.

After we understand the performance of the machine, many customers are also concerned about the sawing ability of this semi-automatic aluminum cutting machine. The following editor will introduce some basic parameters of this machine.

The main parameters of the equipment:

|

Specification |

JC-610-2A |

|

Length range |

500-7000 |

|

Sizing accuracy |

±0.25mm when sawing stroke ≤500mm |

|

Sawing method |

Downward push |

|

Maximum sawing width |

≤500mm |

|

Maximum material height |

≤150mm |

|

Saw blade angle |

90 degrees |

|

Saw blade diameter |

≤600mm |

|

Hardness of sawn profile |

≤15 Webster hardness |

|

Saw cut surface requirements |

Parallelism ±0.15mm (when sawing stroke ≤500) |

Meeting customer needs is the foundation of Jincheng's business.

Welcome friends from the industry to visit the company.

Scan the QR code to read on your phone