Unified national service hotline

NEWS

CONTACT US

Tel:0769-85228059 85194860

Fax:0769-85245586

After-sales service line:0769-85529591

Mail:fu328@126.com

Add:No. 3, Xinlian Xinxing Road, Humen, Dongguan, Guangdong

Taiwan: No. 5, Jingke 7th Road, Nantun District, Taichung City

NEWS CENTER

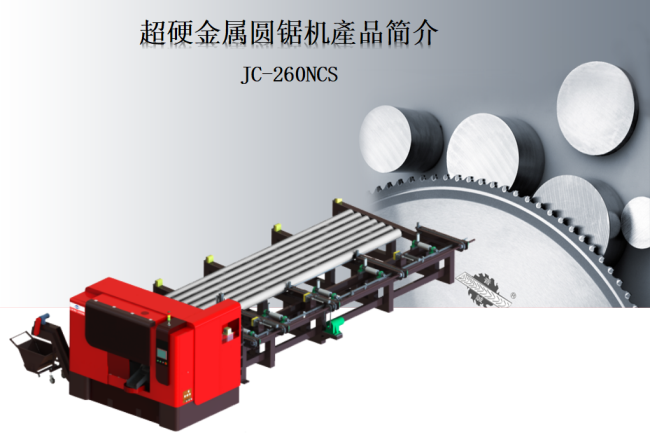

Function description of automatic superhard metal circular sawing machine JC-260NC

- Author:

- Origin:

- Time of issue:2019-09-24 14:30

- Pageviews:

(Summary description)JC-260NC full-automatic high-speed super-hard circular sawing machine is a new type of conventional high-speed sawing machine newly developed by our company. Power source system, electrical control system, cooling system, automatic lubrication system, automatic chip cleaning mechanism, cutting fluid cooling device, power steel brush cleaning device and other parts.

Function description of automatic superhard metal circular sawing machine JC-260NC

(Summary description)JC-260NC full-automatic high-speed super-hard circular sawing machine is a new type of conventional high-speed sawing machine newly developed by our company. Power source system, electrical control system, cooling system, automatic lubrication system, automatic chip cleaning mechanism, cutting fluid cooling device, power steel brush cleaning device and other parts.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-09-24 14:30

- Views:0

JC-260NC full-automatic high-speed super-hard circular sawing machine is a new type of conventional high-speed sawing machine newly developed by our company. Power source system, electrical control system, cooling system, automatic lubrication system, automatic chip cleaning mechanism, cutting fluid cooling device, power steel brush cleaning device and other parts.

2.1 Machine bed:

2.1.1 The main body is made of QT-500 nodular cast iron after tempering to eliminate internal stress and ensure the best rigidity, high strength, and lasting precision.

2.1.2 The box body sheet metal is formed by laser laser cutting and CO2 welding to ensure rigidity and strength.

2.1.3 The base is designed with multi-layer reinforcing ribs, and the internal pressure is eliminated by tempering treatment.

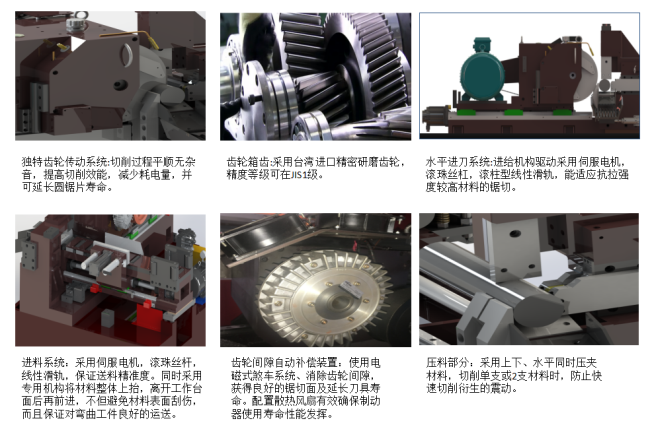

2.2 Spindle power mechanism:

Innovative gearbox design, using high-quality ductile castings after tempering treatment, with precision machining technology imported grinding and high-precision gears. Increase the magnetic powder brake, achieve zero clearance of the spindle, high precision, high torque, saw blade stabilization system, and extend the service life of the saw blade.

2.3 Hydraulic power source system:

Innovative oil circuit design, fully imported hydraulic valves and pumps.

2.3.1 Feeding system:

Motor servo + ball screw horizontal feed to ensure production accuracy, high efficiency and stability.

2.3.2 Clamps:

The main clamp is clamped up and down and horizontally. The Japanese ACT pressure switch is used to ensure the pressure setting value, without adjustment, easy operation and stable pressure.

2.3.3 The main clamp cylinder is made of QT-500 ductile iron after tempering, and the mandrel is made of CR12 chromium steel, heat-treated, ground, and hard chrome-plated. Oil, smooth movement, with components to ensure stable mechanical operation and long life.

2. Main working organization and description

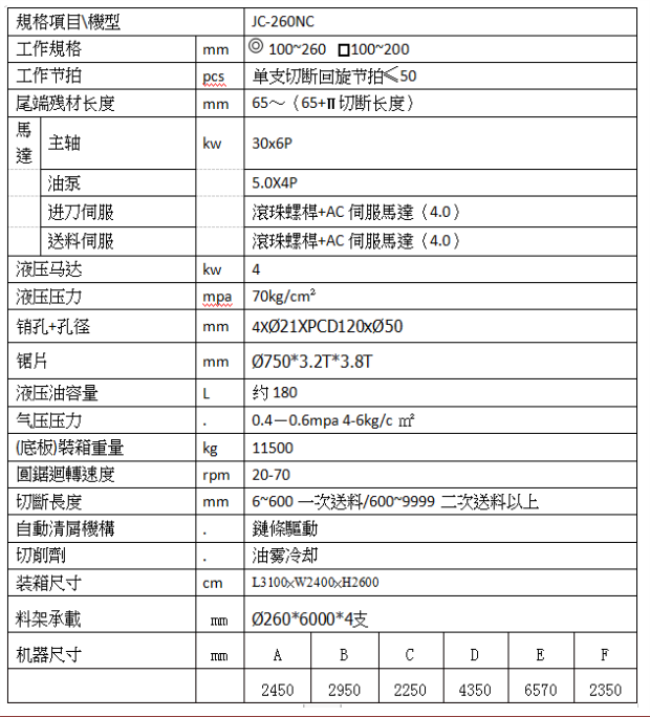

3. Technical parameters

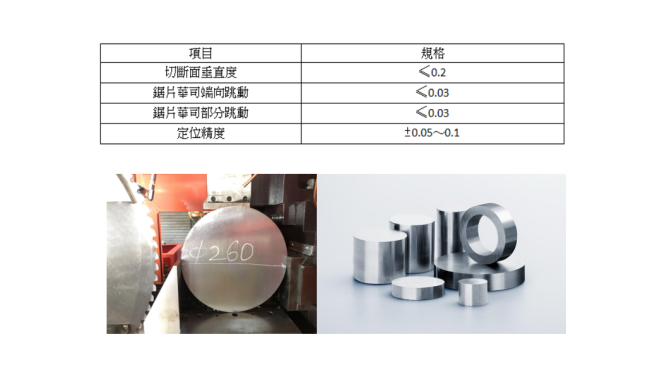

4. Machining accuracy

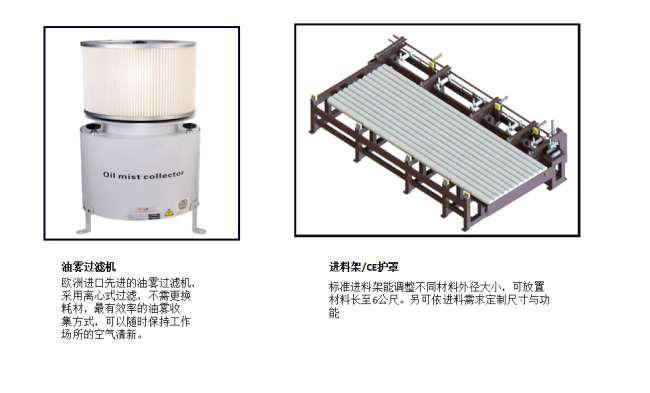

5. Optional accessories

Jincheng Machinery Co., Ltd. is a manufacturing enterprise that integrates design, production, sales and service, and specializes in manufacturing CNC circular sawing machines:

The company has passed ISO 9001:2015 quality management system certification (2016). High-tech enterprise certification (2016). Intellectual Property Management System Certification (2017). Certificates of Intellectual Property Management System, China Forging Association, Best Partner, etc. Jincheng Machinery has been engaged in manufacturing CNC circular sawing machines for more than 20 years. It is the earliest domestic manufacturer and manufacturer of CNC circular sawing machines. It has strong technical force and strong development strength. It has more than 100 products that have won national invention patents and Guangdong Province. Certificate of "Provincial Private Technology Enterprise" awarded by the Department of Science and Technology.

With rich manufacturing experience and R&D capabilities, Jincheng Machinery has continuously established a sound and complete production system.

Processing capacity: Jincheng Machinery Production Base covers an area of 28 acres (18,600 square meters). The processing machine tools include horizontal machining center 630 (Taiwan Dali), 500 (Korea Kia), vertical machining center (1100, 850), large gantry milling, CNC lathes and other precision processing equipment and testing equipment (three-dimensional, two-dimensional, Projector, hardness tester), make the machine reach the standard of high efficiency and high quality.

Research and development capabilities: Jincheng Machinery has designers: 3 senior engineers, 5 general engineers/quality inspectors: 5, sales personnel: 8, electrical engineering 3 people, processing, production, and assembly personnel totaling more than 80 people.

Service power: There are service offices across the country: Tianjin, Sichuan, Chongqing, Hunan, Shanghai, Zhejiang, Anhui, Jiangsu, Shandong, Liaoning, Fujian, Hubei. There are 12 offices in total. The headquarters is in Guangdong.

Scan the QR code to read on your phone