Unified national service hotline

PRODUCTS

CONTACT US

Tel:0769-85228059 85194860

Fax:0769-85245586

After-sales service line:0769-85529591

Mail:fu328@126.com

Add:No. 3, Xinlian Xinxing Road, Humen, Dongguan, Guangdong

Taiwan: No. 5, Jingke 7th Road, Nantun District, Taichung City

PRODUCT CENTER

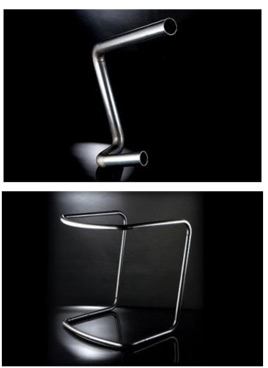

1. It adopts Japanese Mitsubishi A2ASCPU, three-axis control, and at the same time X, Y, Z, three-axis adopt AC servo motors. The action is sensitive and reliable, and high-precision bending workpieces are produced.

1. It adopts Japanese Mitsubishi A2ASCPU, three-axis control, and at the same time X, Y, Z, three-axis adopt AC servo motors. The action is sensitive and reliable, and high-precision bending workpieces are produced.

2.Using a liquid crystal display touch screen, data input and operation are simple and easy to understand.

3.Strong oil pressure direct pressure device to ensure that there will be no deformation when bending thin tubes or small bending radii.

4. The feeding table with automatic clamping nozzle is controlled by numerical value to accurately and quickly position.

5.The high-rigidity and firm swing arm up/down-driving clamp mechanism can clamp the pipe very surely and provide precise bending work.

Applicable materials: steel pipe, stainless steel pipe, purple steel pipe, bronze pipe, aluminum pipe... etc. Standard accessories: wheel mold, clamp mold, guide mold, mandrel.

Special optional accessories: special molds, anti-wrinkle plates, round ball core rods, wheel push devices, automatic core rod lubrication devices, slow retraction devices, and hydraulic oil temperature devices... etc.

Online message

Do you have any good suggestions and comments for our company, or want to consult our products, please fill out the form below, we will get in touch with you as soon as possible!