Unified national service hotline

PRODUCTS

CONTACT US

Tel:0769-85228059 85194860

Fax:0769-85245586

After-sales service line:0769-85529591

Mail:fu328@126.com

Add:No. 3, Xinlian Xinxing Road, Humen, Dongguan, Guangdong

Taiwan: No. 5, Jingke 7th Road, Nantun District, Taichung City

PRODUCT CENTER

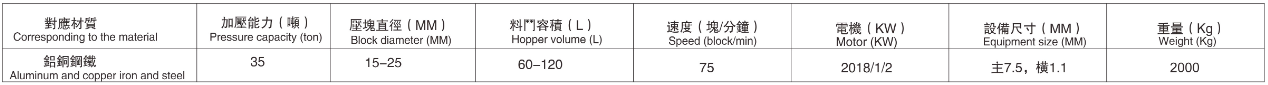

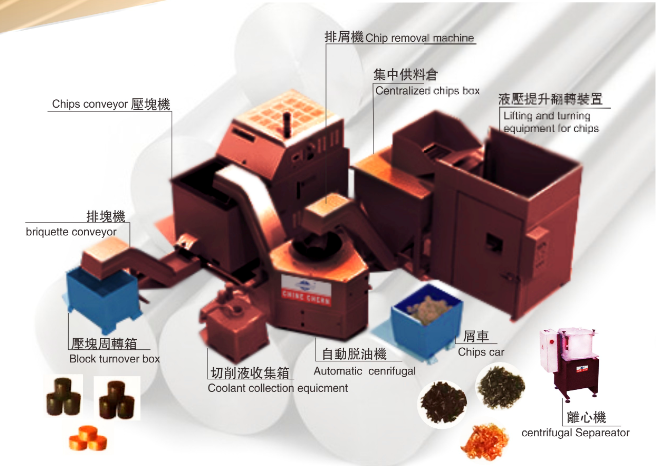

Aluminum and copper chip processing equipment

The basic structure of the equipment is composed of: briquetting machine, block discharging machine, cutting fluid collection box, automatic deoiling machine, chip car, centrifuge, chip removal machine, centralized feeding meeting, and hydraulic lifting and turning device.

Introduction of aluminum and copper chip processing equipment

1. Metal chip briquetting machine:

The metal chip briquetting can realize the briquetting of the chips of non-ferrous metals such as cast iron chips, aluminum chips, steel chips, and recover the cutting oil and liquid attached to the chips, which solves the environmental pollution and transportation inconvenience caused by the chips to the factory , Waste of resources and many other issues.

2. Grinding chip briquetting machine:

The briquetting process is carried out for the grinding debris generated in the factory, and the grinding fluid and oil are recovered at the same time, which not only realizes the oil recovery and reuse, reduces the cost, and greatly reduces the cost of hazardous waste treatment.

3. Crusher:

Aiming at the near-crushing treatment of the on-site clumped chips, the chip volume can be reduced and the briquetting process can be facilitated.

4. Deoiling machine:

De-oiling the chips at the customer's site by centrifugation realizes the recovery of oil and liquid, and improves the utilization rate of oil.

5. Auxiliary conveying and feeding equipment:

Automated processing of chips at the customer's site is achieved through buffering and transmission equipment.

Online message

Do you have any good suggestions and comments for our company, or want to consult our products, please fill out the form below, we will get in touch with you as soon as possible!